Accelerate Product Development with Rapid Prototyping

- Faisal Kapasi

- Feb 11

- 4 min read

In today’s fast-paced industrial landscape, speed and precision are critical. When developing new products, you need to move quickly from concept to reality without sacrificing quality. This is where prototyping solutions come into play. They allow you to test ideas, refine designs, and identify potential issues early in the process. By doing so, you reduce costly errors and shorten your time to market.

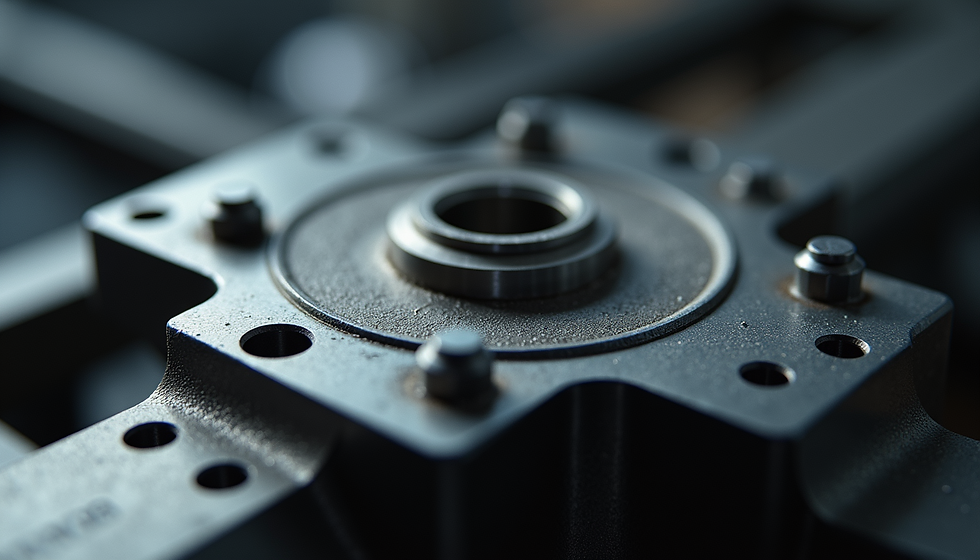

Prototyping is not just about creating a model; it’s about creating the right model that accurately represents your final product. This approach is especially important for precision metal components, where tolerances are tight and performance is non-negotiable. In this article, I will walk you through how prototyping solutions can accelerate your product development cycle and help you deliver superior results.

Understanding Prototyping Solutions in Product Development

Prototyping solutions encompass a range of techniques and technologies designed to create physical or digital models of a product before full-scale manufacturing begins. These solutions help you visualise and test your design in real-world conditions.

There are several types of prototyping methods, including:

3D Printing: Ideal for quick, low-cost models with complex geometries.

CNC Machining: Offers high precision and is suitable for functional prototypes.

Casting and Moulding: Best for metal parts that require exact replication of final production processes.

Each method has its strengths and is chosen based on the product’s requirements, material, and intended use. For precision metal components, casting-based prototyping solutions often provide the most accurate representation of the final product’s properties.

Using prototyping solutions early in the design phase allows you to:

Identify design flaws before mass production.

Test material properties and performance.

Gather feedback from stakeholders and end-users.

Reduce development costs by avoiding late-stage changes.

How Prototyping Solutions Speed Up Development Cycles

Time is a critical factor in product development. The faster you can iterate and validate your designs, the sooner you can launch your product. Prototyping solutions enable rapid iteration by providing tangible models that can be evaluated and modified quickly.

Here’s how prototyping solutions accelerate your development:

Faster Design Validation: Instead of relying solely on computer simulations, you get a physical model to test fit, form, and function.

Improved Communication: Physical prototypes help teams and clients understand the product better, reducing misunderstandings.

Early Problem Detection: Issues such as assembly difficulties or material weaknesses become apparent early.

Streamlined Manufacturing Setup: Prototypes can be used to fine-tune manufacturing processes, reducing setup time and errors.

For example, when working with complex metal components, a prototype cast can reveal subtle issues in the design that might affect casting quality or mechanical performance. Addressing these early saves weeks or even months in the production timeline.

Leveraging Rapid Prototyping Services for Precision Metal Components

To truly benefit from prototyping solutions, partnering with experts who offer rapid prototyping services is essential. These services specialise in producing high-quality prototypes quickly, using advanced casting and machining techniques tailored to your needs.

Rapid prototyping services provide:

Material Expertise: Access to a wide range of metals and alloys suitable for your application.

Precision Manufacturing: Tight tolerances that match your final production standards.

Customisation: Ability to create complex geometries and intricate details.

Speed: Fast turnaround times that keep your project on schedule.

By outsourcing your prototyping needs, you can focus on design and development while experts handle the technical challenges of producing accurate prototypes. This collaboration ensures your prototypes are reliable and representative of the final product.

Best Practices for Integrating Prototyping Solutions into Your Workflow

To maximise the benefits of prototyping solutions, it’s important to integrate them effectively into your product development process. Here are some practical recommendations:

Start Early: Incorporate prototyping at the concept stage to catch design issues before they become costly.

Define Clear Objectives: Know what you want to test with each prototype - whether it’s fit, function, or material properties.

Iterate Quickly: Use feedback from each prototype to refine your design promptly.

Collaborate Closely: Maintain open communication between design, engineering, and manufacturing teams.

Document Changes: Keep detailed records of modifications to track improvements and decisions.

By following these steps, you create a structured approach that leverages prototyping solutions to reduce risk and improve product quality.

The Future of Product Development with Prototyping Solutions

As technology advances, prototyping solutions continue to evolve. Innovations in additive manufacturing, materials science, and digital simulation are making prototypes more accurate and easier to produce.

Looking ahead, you can expect:

Increased Use of Hybrid Techniques: Combining 3D printing with traditional casting for complex metal parts.

Enhanced Digital Twins: Virtual prototypes that complement physical models for comprehensive testing.

Sustainability Focus: Using eco-friendly materials and processes in prototyping.

Greater Customisation: Tailored prototypes that meet specific industry standards and client needs.

Embracing these trends will help you stay competitive and responsive to market demands. Prototyping solutions are not just a step in development; they are a strategic tool for innovation and quality assurance.

By integrating advanced prototyping solutions into your product development, you position yourself to deliver precision metal components that meet exacting standards. This approach reduces time to market, minimises risk, and ensures your products perform as intended. Whether you are refining a new design or preparing for large-scale production, prototyping solutions are an indispensable part of your success strategy.

Comments